What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

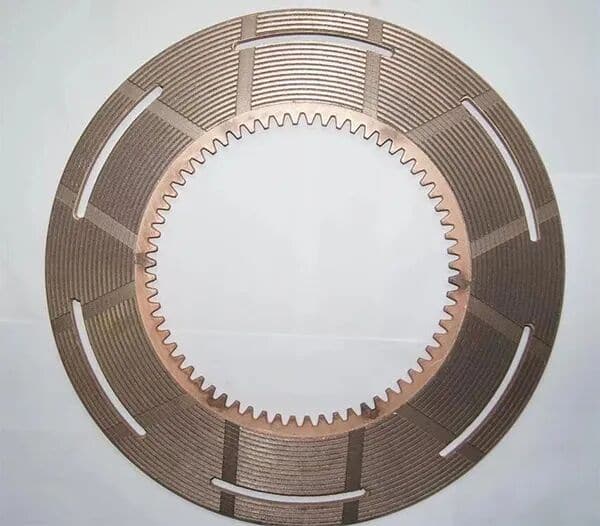

Bulldozers are heavy-duty machinery that play a vital role in large-scale construction projects. However, like all mechanical equipment, bulldozers require regular maintenance and servicing to ensure proper operation. The friction plates within the bulldozer's transmission are among the critical components; should these parts become damaged, it can severely impact the machine's performance. This article will detail the consequences of failing to replace damaged friction plates in a bulldozer's transmission.

First, let us understand the function of friction plates. As one of the critical components within the transmission, they assist in controlling the bulldozer's speed and power output through friction with other metal parts. Should the friction plates become damaged, they will fail to operate correctly, consequently leading to a decline in the bulldozer's performance. Secondly, damaged friction plates can also cause wear on the transmission bearings and result in gear engagement issues. Their function is to enable smooth gear changes during start-up, acceleration, and deceleration. Should these plates become damaged or worn, they cannot perform correctly. This may manifest as sudden speed fluctuations, unstable power delivery, and poor starting performance. Consequently, operating the bulldozer becomes significantly more challenging and hazardous.

Worn friction liners may also impact other components within the bulldozer. When friction liners fail, associated parts such as gears, shafts, and other mechanical assemblies may sustain damage. Should these components be compromised, replacement or repair becomes necessary, incurring additional costs and prolonging downtime. Ultimately, failure to replace worn friction liners in a timely manner may shorten the bulldozer's overall service life. As consumable components within the bulldozer's transmission system, friction liners typically possess a finite service life under normal operating conditions. Failure to replace them promptly accelerates wear and damage, adversely affecting the machine's overall operational lifespan. This may necessitate more frequent servicing and maintenance, thereby increasing the equipment's upkeep and operational costs.

In summary, within the bulldozer transmission, friction plates are critical components. Should these parts become damaged, it will adversely affect the bulldozer's performance and reliability. Therefore, the timely replacement of damaged friction plates is paramount, as this will help ensure the bulldozer's proper functioning and extend its service life.

Is your bulldozer losing power or showing signs of transmission wear?

Don‘t wait for costly breakdowns. Our heavy-duty OEM friction plates ensure smooth operation and long transmission life.

What performance tests are required for wet clutch friction plates?

What performance tests are required for wet clutch friction plates?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

A Casual Discussion on Brake Pad Friction Materials

A Casual Discussion on Brake Pad Friction Materials

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions