Beyond the Datasheet: A Deep Dive into the Friction Performance of Woven Clutch Facings

Dear fellow engineers, there is always a need to balance high torque transmission capacities together with good engagement performance. This is a big challenge in clutch system design and selection. It is this key engineering tradeoff which is answered by a component that is generally described in overly simplified form in product literature: the complete friction performance of the clutch facing.

We get static parameters from datasheets, which is just the first thing to look at: an incomplete picture. True performance is shown at work. Article 10 discusses about how woven Clutch faceings behave in the 'real World' as compared to the basics. We will also analyze what is the performance of it under heat and pressure, how fast do the sliders slide. Study for its material and engineering side.

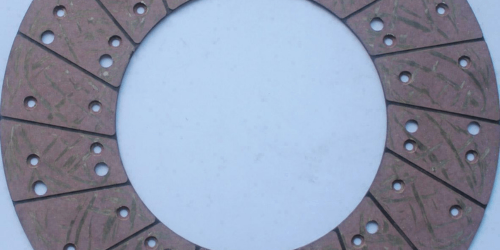

Trait 1: A Robust Foundation: Structure advantage & frictional stable of woven process

The performance of the woven clutch facing comes from its unique production process. they consist of continuous highstrengthfibre yarns ( e. g. glass fibre ) that are woven and impregnated with resin binders. This structure has very good mechanical and bursting strength, so it can work at high pressures and speeds. More significantly, it also offers a very stable and reliable Static and Dynamic μ (static and dynamic coefficient of friction) And it is convenient for us to control more precisely the clutch engaging properties at the design time so as to lay down a good foundation for smooth and shudder-free engagemen.

Trait 2: Performance in Extreme Conditions: Superior thermal fade resistance, recovery

Thermal fade and recovery are key metrics for measuring friction materials’ performance, significantly affecting system reliability under extreme circumstances. The facing with woven fabric works well here because it is breathable and can withstand heat. Porosity: for easy heat transfer and remove debris,thermal stable material system: for fading resistance(coefficient of resistance doesn’t suddenly decrease with high temperature) Even if they overheat because of too many changes or hill climbing with a lot of weight, they go back to being great at rubbing together when temps drop. It’s a vital function that makes sure dependable,constant power transfer is possible under tough conditions.

Trait 3: Evidence in Data: A Scientific Way to Figure Out Test Report

Rigorous engineer need to rely on believable Woven Clutch FACING Performance Test data: And usually they come from the kind of normal friction tests that Chase and Krauss do. A good complete report will have a graph of coefficient of friction v temp and press. and speed. Engineers need to look at these plots - The μ-Temp curve (to figure out when the fade begins and where the stable high temp region is), the Restore Curve (shows that performance bounces back once things cool off ) and wear rate. We can also get a sense from being able to read this changing data, as to how we might successfully fit a part into a system.

Conclusion

In summary, the main point of woven clutch facings is the three major benefits of stability in friction coefficient, strong fade resistance in thermal competition conditions, high mechanical strength and good recovery. And they’re great for lots of tough transmission jobs too because of these properties.

At the end of the day, the outcome of the clutch system relies on picking the right kind of material supported by solid data. We encourage you to speak to us directly on an engineers standpoint, be it for any extra detailed Technical Data Sheets (TDS) or discussing the performance test reports that are specific to your required application projects with our application engineering teams. Here for ya. lets us work together for you next system design to be better

Yida Friction – Your Partner in Performance and Value

What performance tests are required for wet clutch friction plates?

What performance tests are required for wet clutch friction plates?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

A Casual Discussion on Brake Pad Friction Materials

A Casual Discussion on Brake Pad Friction Materials

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions