What is Paper Friction Material? Composition, Benefits & Production Steps

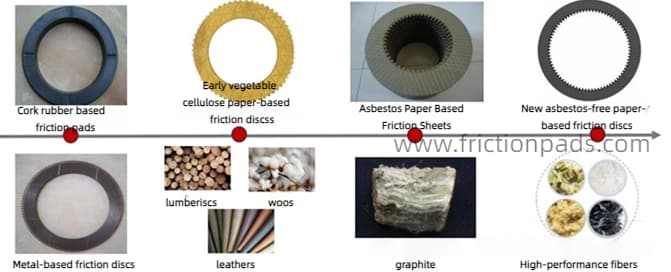

Originated in the 1950s, paper-based friction material is a new type of porous and highly elastic friction material. Due to its advantages of low cost, stable dynamic friction factor, close dynamic/static friction factor ratio, smooth fitting performance, low noise, and protection of dyadic materials, it has been widely used in wet clutches and brakes in various types of vehicles, construction machines, machine tools, ships, and mining machinery industries. Which with the progress of the times, the material components of the friction plate is also constantly iterative update, from cork rubber-based and sintered metal-based wet friction materials to plant cellulose-based paper-based friction materials, and then asbestos paper-based friction materials, and finally evolved into a modern high-performance fibers of the new paper-based friction plate. This step by step, reflecting the innovative spirit of paper-based friction material researchers.

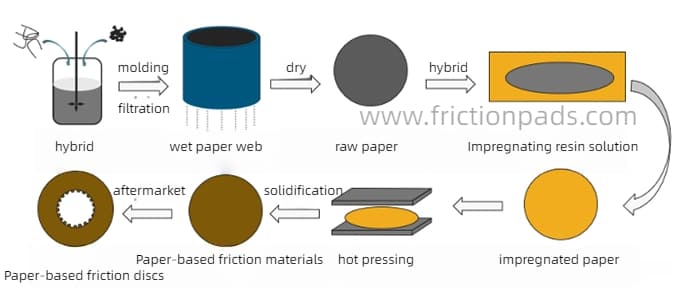

Definition: Paper-based friction material is based on reinforcing fibers, with fillers, a variety of friction performance modifiers, binders and other components, and then through the original paper copying, impregnation, hot pressing, curing and other process molding.

Fig. 2 Components of paper-based friction materials

Third, the core process of the preparation process:

3.1:Pulping: fibers (such as cotton fiber, carbon fiber) and friction regulators mixed into slurry.

3.2:Paper copying: through the papermaking process to form a porous fiber substrate.

3.3:Impregnation: impregnated with phenolic resin and other binders, to enhance the strength of the material.

3.4:Curing hot-pressing: molding at high temperatures and high pressures, to form a dense structure.

IV. Main areas of application:

4.1:Vehicle wet clutch and brake: paper-based friction material plays a vital role in these parts, providing stable and reliable friction transmission and braking effect.

4.2:Construction machinery transmission: in construction machinery, paper-based friction material is used to ensure the smooth operation of the transmission system.

4.3:n the wet drive axle of construction vehicles (e.g. mining trucks, excavators), paper-based friction material is used in the wet drive axle of construction vehicles (e.g. mining trucks, excavators), paper-based friction material is used in the wet drive axle of construction vehicles, e.g. mining trucks, excavators). In wet drive axles for construction vehicles (e.g. mining trucks, excavators), paper-based friction materials are used in the clutch or braking system to provide stable torque transmission and anti-wear properties.

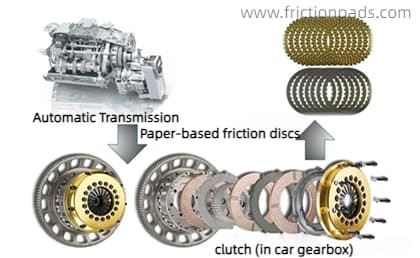

4.4:Automatic transmissions in cars and clutches in motorcycles: In these applications, paper-based friction materials also play an important role in improving transmission efficiency and safety.

4.5 wind power gearbox wet clutch: paper-based friction material in the wind turbine to withstand high torque and frequent start-stop, to protect the reliability of the transmission system.

Fig. 4 Schematic diagram of automatic transmission, clutch and paper-based friction plate

5.1:Excellent friction performance: dynamic/static friction coefficient is close to (0.12-0.18), smooth transmission, low noise.

5.2:Porous structure: oil absorption and heat dissipation ability is strong, suitable for long-term oil lubrication environment.

5.3:Low cost: compared with the copper-based powder metallurgy material, the raw material and production costs are lower.

For technical data sheet or samples of paper-based friction materials, pleasecontact our engineer team!

What performance tests are required for wet clutch friction plates?

What performance tests are required for wet clutch friction plates?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

A Casual Discussion on Brake Pad Friction Materials

A Casual Discussion on Brake Pad Friction Materials

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions