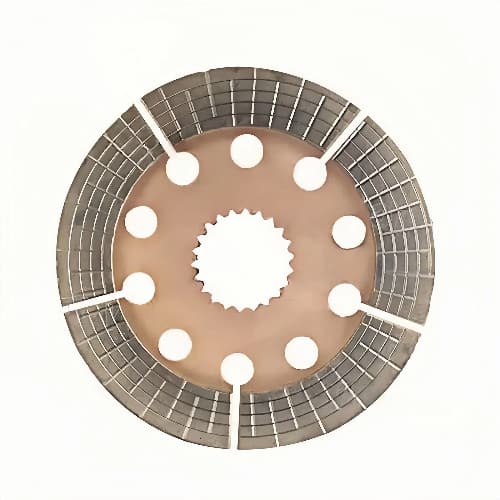

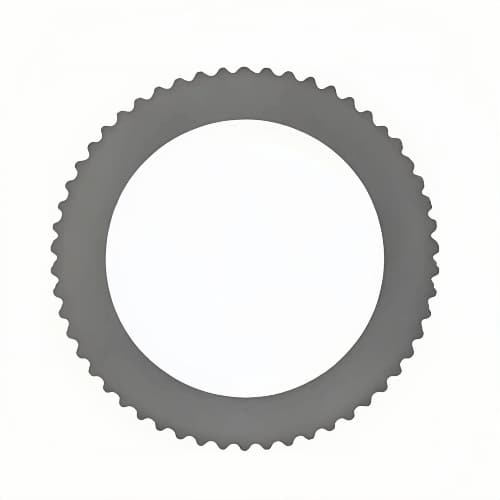

C9NNP743A PTO clutch plate for Ford New Holland 5610/8630/TS110 tractors. 148.6mm composite disc with 52-tooth spline (112.24mm OD). 30% longer lifespan. Global shipping.

For OEMs and distributors demanding reliability:

✓ Engineered Excellence - 800-ton press forged components

✓ Certified Quality - SAE J661 validated performance

✓ Global Supply Ready - 45-day standard inventory

✓ Customization Experts - Your drawings, our execution