Clutch Plate Product Function Introduction

Clutch Plate Role:

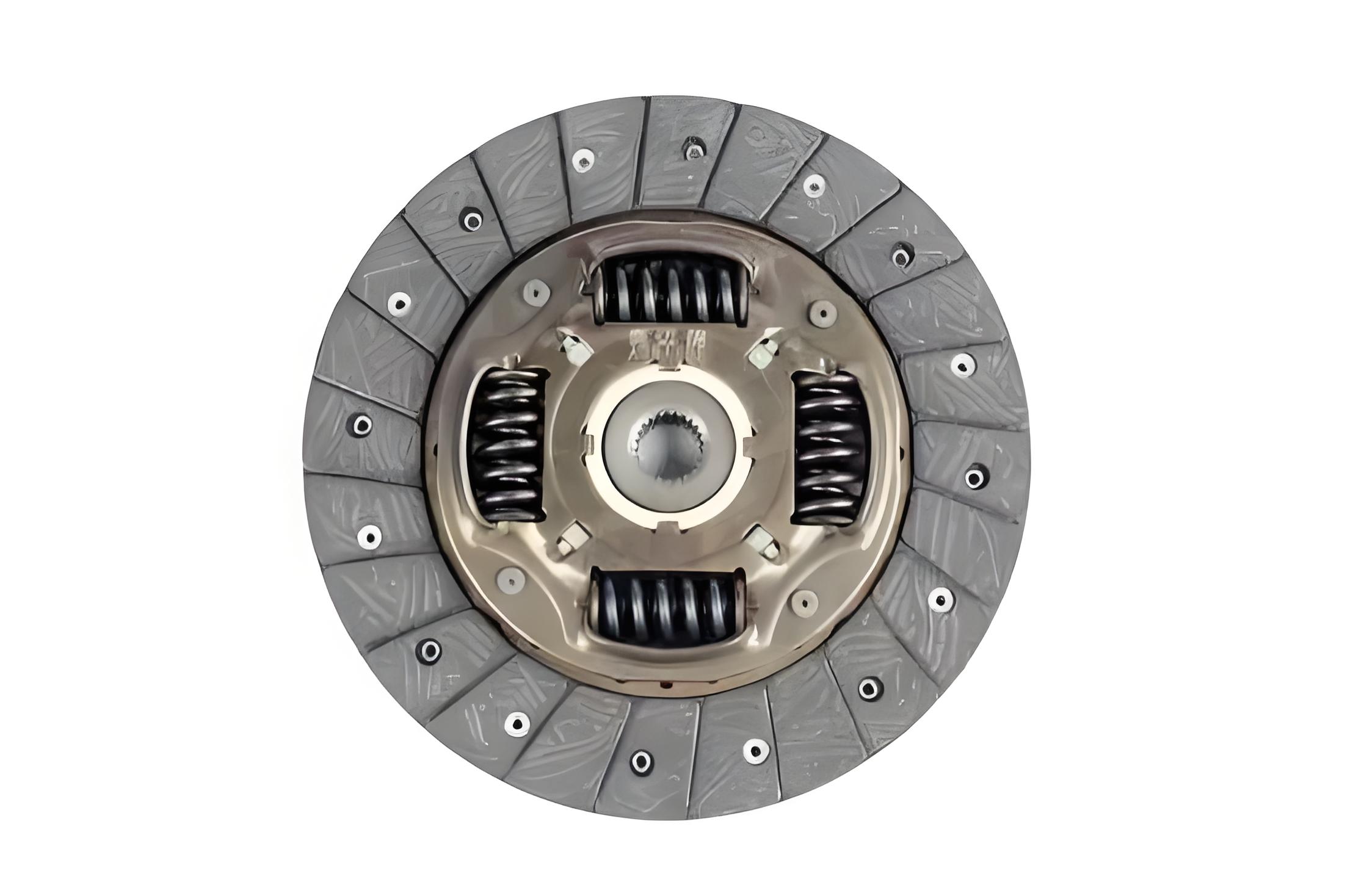

Serves as a medium for transmitting engine power to the transmission. Clutch Disc (Clutch). These friction materials are mainly asbestos-based friction materials, and with the increasing demand for environmental protection and safety, semi-metallic type friction materials, composite fiber friction materials, and ceramic fiber friction materials are gradually emerging. Ordinary type automobile clutch plate, assembled from friction plate, disk hub, damping spring, damping disk, damping plate and other parts, in the process of automobile driving, step on the clutch pedal, the clutch plate will be separated from the engine flywheel, in the high gear to switch to a low gear by the high gear, when the clutch plate is connected with the engine flywheel, with the reduction of engine speed, the car is forced to drop to the speed of the engine speed and match the driving speed of the engine, and its own inertial kinetic energy is automatically consumed.

Clutch Function:

is a composite material with friction as its main function and structural performance requirements. Friction materials for automobiles are mainly used for the manufacture of brake and clutch discs. These friction materials mainly use asbestos-based friction materials, and with the increasing requirements for environmental protection and safety, semi-metallic type friction materials, composite fiber friction materials, and ceramic fiber friction materials have gradually emerged. As the friction materials are mainly used in the manufacture of brake and transmission parts in automobiles, they are required to have a sufficiently high and stable coefficient of friction and good wear resistance.

Clutch plate working principle:

ordinary automobile clutch plate, assembled from friction plate, disk hub, damping spring, damping disk, damping plate and other parts, in the process of automobile driving, step on the clutch pedal, the clutch plate will be separated from the engine flywheel, in the high gear to switch to a low gear, when the clutch plate and the engine flywheel is connected, along with the reduction of the engine speed, the automobile is forced to drop to and the engine speed to match the driving speed, the clutch plate and the engine flywheel are connected, with the reduction of the engine speed, the car is forced to drop to and the engine speed to match the driving speed. As the engine speed decreases, the car is forced to drop to a speed that matches the engine speed, and its own inertial kinetic energy is automatically consumed.

CVT clutch plate is uniquely humanized and intelligently designed according to the principle of automobile driving thrust. When the engine speed decreases in high-speed driving, if the driving speed of the car is greater than the engine speed, the clutch plate and the engine flywheel will be automatically separated, and the car will continue to drive at high speed using its own inertia; and when the driving speed of the car is reduced to match with the engine speed, the clutch plate and the engine flywheel will be automatically combined to enter into the driving state. Thus realizing the automobile in the driving release the throttle that is automatically transferred to the coasting state, step on the gas pedal can be automatically transferred to the driving state.

What performance tests are required for wet clutch friction plates?

What performance tests are required for wet clutch friction plates?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

What consequences may arise from the deterioration of friction plates within a bulldozer's transmission?

A Casual Discussion on Brake Pad Friction Materials

A Casual Discussion on Brake Pad Friction Materials

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions

Prevent Downtime! Marine Anchor Brake Band: Fault Diagnosis, Repair & Proactive Maintenance Solutions