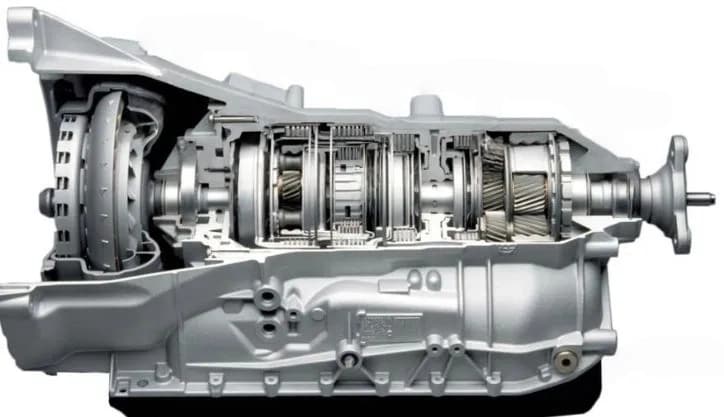

Commercial Vehicle Automatic Transmission Friction Pads Market Opportunities

The current global commercial vehicle transmission market is still dominated by manual transmissions (MT), which account for about 58% of the international market.

However, with the breakthrough of automatic transmission technology, hydro-mechanical automatic transmission (AT) and electro-mechanical transmission (AMT) are accelerating the penetration in the field of heavy commercial vehicles by virtue of the two core advantages of fuel economy improvement and driving comfort optimization. This transformation trend will directly drive the incremental demand for automatic transmission friction plates.

Urbanization and Logistics Demand Drive Popularity of Automatic Transmissions

Accelerated urbanization and expansion of the logistics industry have significantly increased the intensity of commercial vehicle use, while urban traffic congestion has further amplified the demand for easy-to-operate automatic transmission models.

Taking AMT as an example, its transmission efficiency is as high as 99%, which is nearly 10 percentage points higher than AT, and its production cost is 30% lower, and its maintenance cost is close to that of manual transmission (MT), which is a significant advantage in the cost-sensitive commercial vehicle market.

Hybridization Trend Expands Incremental Space

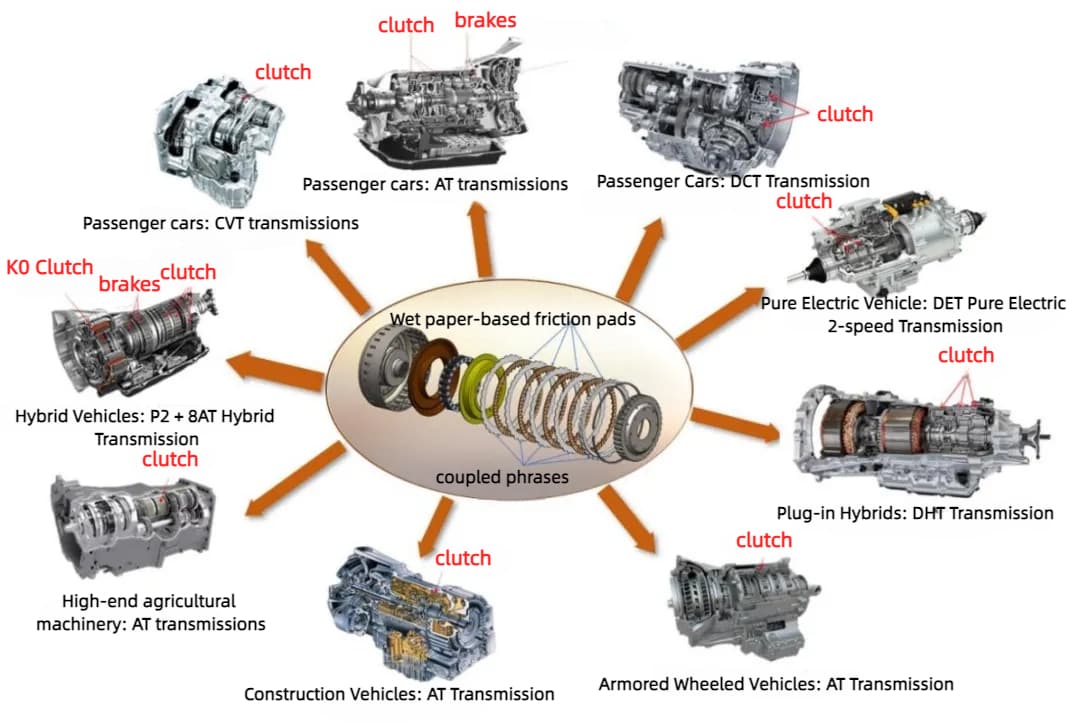

Hybrid technology has become a key direction in the path of energy saving for commercial vehicles. Hybrid vehicles (HEV/PHEV) need to rely on automatic transmission to realize power coupling, friction plate as the core transmission components demand continues to grow.

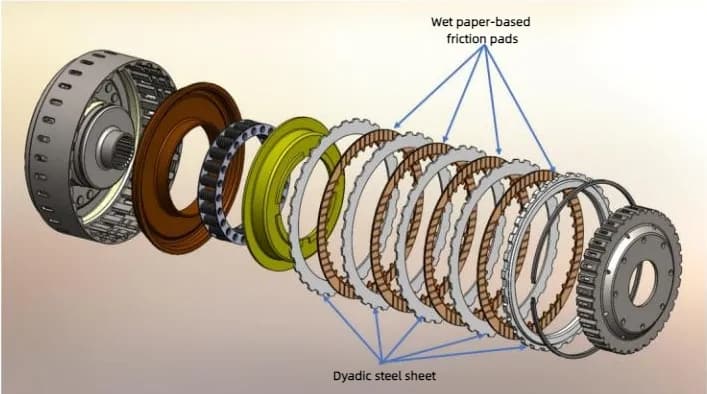

Wet paper-based friction pads for braking and transmission in conjunction with dyadic pads

It is predicted that the proportion of hybrid vehicles in passenger cars will reach 55% in 2035, while the hybridization process of intercity logistics vehicles in the field of commercial vehicles will accelerate at the same time. According to research studies, specialized hybrid electric drive systems (such as DHT) and multi-gear design will become mainstream, further expanding the application scenarios of wet friction pads.

Friction Plate Technology: Core Advantages of Wet Paper-Based Materials

Friction plates for automatic transmissions consist of wet paper-based friction plates and dyadic plates that transmit power through oil film tension:

Wet paper-based friction pads are covered on both sides by counterparts

Wet paper-based friction discs are made of cellulose fibers, with porous and compressible characteristics, high coefficient of dynamic friction and close static/dynamic friction coefficients, low noise and wear when transmitting torque, and a life span of up to 5-6 times that of dry clutches.

◎Coupling plate is made of steel stamping and molding, staggered assembly with friction plate, which enhances friction and reduces the shear loss of oil film, ensuring smooth and controllable power transmission.

◎ Compared with powder metallurgy and carbon-based materials, paper-based materials have become the dominant choice for automatic transmission friction plates due to their high abrasion resistance, supple bonding characteristics, and low cost advantages.

Definitive Path to Incremental Market

The promotion of AT/AMT in commercial vehicles and the trend of hybridization form a dual drive:

Efficiency and cost balance: AMT continues MT's high transmission efficiency (99%) while reducing operating complexity, making it more suitable for long-distance standard-duty conditions; AT improves heavy-duty starting ability through torque converter, making it suitable for complex road conditions.

Accelerated domestic substitution: the global automatic transmission friction plate market is undergoing supply chain restructuring, and Chinese suppliers are rapidly cutting into the international supply chain. China's friction plate supply chain has a significant cost advantage: the price of similar products is 25-30% lower than that of Europe and the United States, and the lead time is shortened by 40%.

Market space: the global AMT friction plate market size will reach $5.8B in 2025, and the substitution rate of Chinese suppliers in the non-U.S. and Japanese markets has already exceeded 15%. Has exceeded 15%

Summary

Increasing penetration rate of automatic transmissions in commercial vehicles and popularization of hybrid technology will jointly promote the continuous expansion of the wet paper-based friction pad market. As a friction plate importers need to be keen to capture this opportunity, to grasp the window of substitution, to seize the incremental dividends.